Motorized folding machines MAXI MAXI, MAXI SH, MAXI DUO, MAXI 3SH

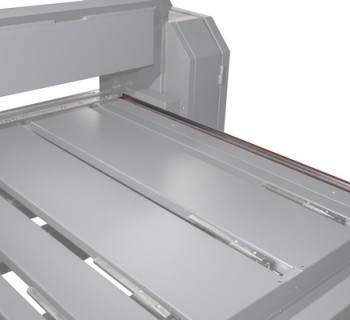

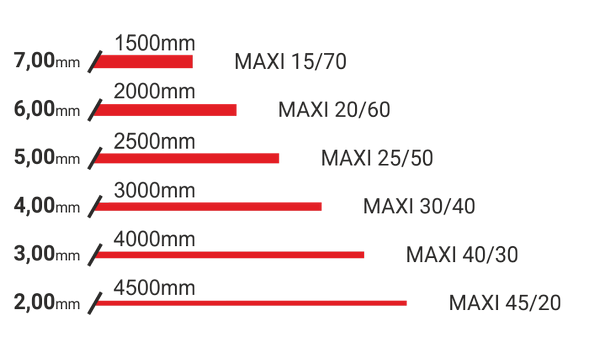

Folding machines type MAXI are among the best performing ones in terms of capacity resources when folding the material up to a length of 4,5 m at a thickness of 7 mm. Load-bearing parts of the machine are made as massive welded steel construction which, coupled with powerful motors, provides the required performance parameters. A pair of trapezoidal screws drives the clamping beam, which leads out the required pressure force for the massive machine table. The folding beam has also a dual drive, which eliminates the twisting, especially during longer working lengths.

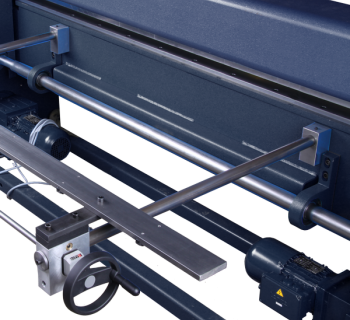

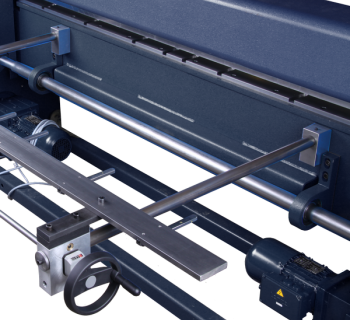

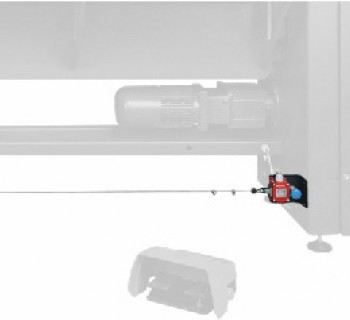

When handling long and heavy panels, the motorized back gauge can be used suitably, which pushes the material into the folding space and allows you to operate the machine with only one operator. Machines are equipped with tools (segments and blades) of high strength steel (1100 N/mm2). The machine enables high opening (up to 300 mm). The version DUO provides a wide range of possibilities, and the appropriate control system increases flexibility and productivity. It is suitable for folding various types of raw materials, especially stainless steel products.

They are manufactured in these versions:

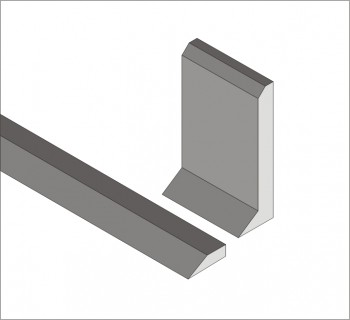

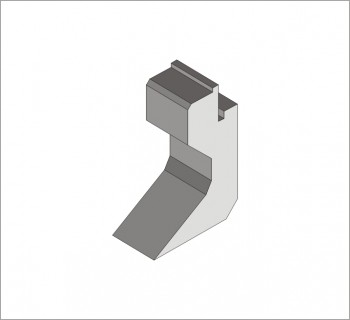

MAXI -blades on all free beams

MAXI SH - high segments on the clamping beam, blade on the folding beam and the bed beam

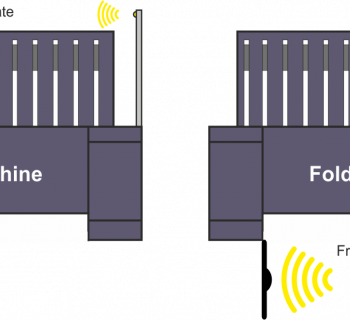

MAXI DUO - on the same machine,there can be on the clamping beam a blade or SH segments

MAXI 3SH - segments on all three beams, on the clamping beam the segments are high

Standard equipment:

- tools according type of machines

- manual adjustment of one folding angle (type MA)

- manual crowning adjustment for folding beam

- foot switch

- storage for blade (only for MAXI DUO)

- connecting plug 32 amp, 3 x 400 V, 5 meter cable (within the EU)

Producer reserves the right to change all specifications subject without notice.